Used Car Tyre Oil Extraction By Pyrolysis Process

- Packaging:

- Seaworthy packing 2*40HQ

- Productivity:

- 200 sets per year

- Brand:

- SIHAI

- Transportation:

- Ocean,Land,Air

- Place of Origin:

- Henan

- Supply Ability:

- 200 sets per year

- Certificate:

- CE ISO

- HS Code:

- 8419409090

- Port:

- Lianyungang,Qingdao,Shanghai

Basic Info

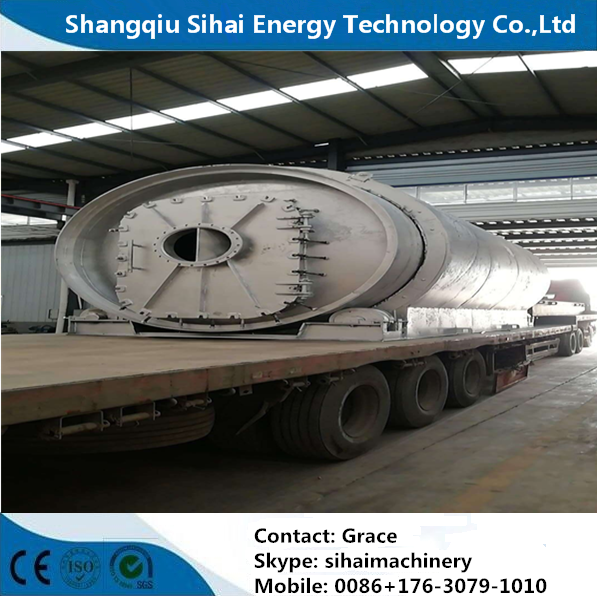

Model No.: LJ-10

Product Description

Used Car Tyre Oil Extraction By Pyrolysis Process

Introduction of Used Car Tyre Oil Extraction By Pyrolysis Process:

This plant does not have to get rid of silt, moisture content, iron wire impurity and so on from the scrap plastic, directly loads in the rotary system high temperature atmospheric pressure split processor, catalyses, heats up, distils oil steam, the oil gas through the condenser, the liquefied part condense into the oil mixture, and the unliquefied part holds through the fuel gas system into the processor bottom to burn.After the mixture oil condense, put into fractionation processor to heat though catalytic reforming process, and get the oil steam. Then the oil steam through the condenser to be basic fuel, and add various additives to become qualified fuel.

Main components of Used Car Tyre Oil Extraction By Pyrolysis Process:

a. Host horizontal rotary pyrolysis processor.

b. Feeding system

c. Pressure and temperature alarm system

d. Secondary catalytic tower

e. Automatic slag removal system

f. Central electronic control system

g. Tank cooling system

h. Gas heating system (exhaust gas treatment system)

i. Dust and dust removal system

Raw materials of Used Car Tyre Oil Extraction By Pyrolysis Process:

Item Raw Materials Output Tyres Steel wire tyre 40%--50% Nylon tyre ≈40% Bicycle tyre ≈35% Paper pulp Coarse material ≈15% Water washing material 23%-26% PE material ≈70% Cable skin PE cable skin ≈85% PVC cable skin ≈25% Pure rubber cable skin ≈35% Telephone wire ≈50% Life Garbage Pure plastic bag ≈50% Coarse material with water ≈15% shoes Sports shoe`s sole 27%-33% Black rubber ≈35% Gum outsole ≈45% Others Common rubber pipe ≈30% Carpets ≈35% Aluminum foil ≈30% Car glass bead ≈50% PP Beverage bottle ≈50%

End product of Used Car Tyre Oil Extraction By Pyrolysis Process:

Name Percentage Usage Tyre oil 40%~45% * can be sold directly as fuel. * can be refine to diesel and gasoline by oil distillation plant Carbon black 37% * can be sold directly. * can be refined by carbon black processing machine to make it finer (1500mesh finer). *can be made into pellet by pellet machine Steel wire 13% *can be sold directly as steel or iron. Waste gas 5% * can be recycled to heat up the reactor

Technical parameter of Used Car Tyre Oil Extraction By Pyrolysis Process:

| Model | Raw material | Structure form | Cooling system |

| LJ-9 | Waste tire, plastic, rubber | Horizontal | Water cooling |

| Heating method | Oil output rate | Power | Installation |

| Directly | 45% | 15.5KW | Foundation |

| 24 hours processing capacity | 24 hours oil output | Work pressure | Host speed |

| 8-10 tons raw materials | 3.2-4.5 tons fuel oil | Atmospheric | 0.4r\min |

| Transport | Reactor size | Working form | Weight of reactor |

| External gear drive | 2200*6600mm | Batch | 29 tons |

Product Categories : Waste Tire Pyrolysis Plant